- Product Display

- Product Display > High Frequency Welding Machine > Canvas/Tarpaulin/Tent/Membrane Welder

25KW Auto Walking High Frequency PVC Large Covers Welding machine

| Model: | HR-25KWA |

| Scope Of Application: | samples can be quick weld by high frequency, machine can be used to make car tarpaulin canvas, tent cloth, movie screen, PVC methane tank, PVC children swimming pool, film structure etc. |

| Features: | 1 a seam is done by one time with good looking , no wrinkles, no tool marks and smooth and beautiful surface.2 Using the smart man-machine interface PLC operating system, step or servo motor drived.3 Automatic walking, precise location, without moving |

Application:

It is especially designed for HF welding of large format structural membranes, pool-liners, oil-booms, water cisterns, tarpaulin, tents, tensile structures, advertising billboards, spark protection cloth ,tent of truck, canvas of agricultural,canopy, swimming pool covers and other PVC/PU technical textiles, large PVC canvas/digesters/ fabric, computer advertising / printing/ Film cloth, the membrane structure, etc.

Products:

Machine General Features:

| 1. Servo-motor; Touch screen programmable HMI / PLC |

| 2. European-model square high frequency vibration box, more reliable and stable in output |

| 3. Single line or two lines continue welding, welding length can be ordered as special need. |

| 4. Can be used as a freestanding machine for welding production or as a supplement to a larger system. |

| 5. CE rated machine; factory verified by SGS and BV; |

| 6. Customer's site installation, training & maintenance available |

| 7. Double Operator Control Press Pedals – on both sides of machine for ease of access and material positioning during welding of complex shapes of fabric |

| 8. Online service by Email, Fax, Video Online- allowing remote live video servicing of basic setup and repairs through the use of face-to-face online video. |

| 9.Customized work table dimensions, electrode holder dimensions, tooling |

| 10.Laser Guide Projectors – projecting laser lines (easy for operator's eyes) for quick material guidance on the work table |

| 11. High frequency welding press pneumatically operated |

|

12. C-Frame / G frame welded steel structure with integrated HF generator |

|

Technical Parameters:

1. HF Filter unit available 2. Auto-high frequency tuning technology 3. Precision straight bar welding up to 1500x50mm 4. Vacuum table available 5. Welding electrode temperature thermosta

Welded Samples: |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

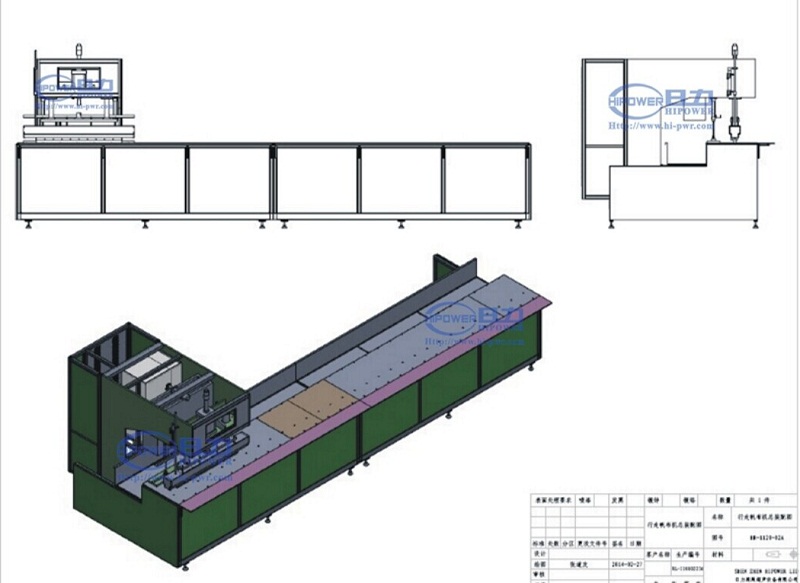

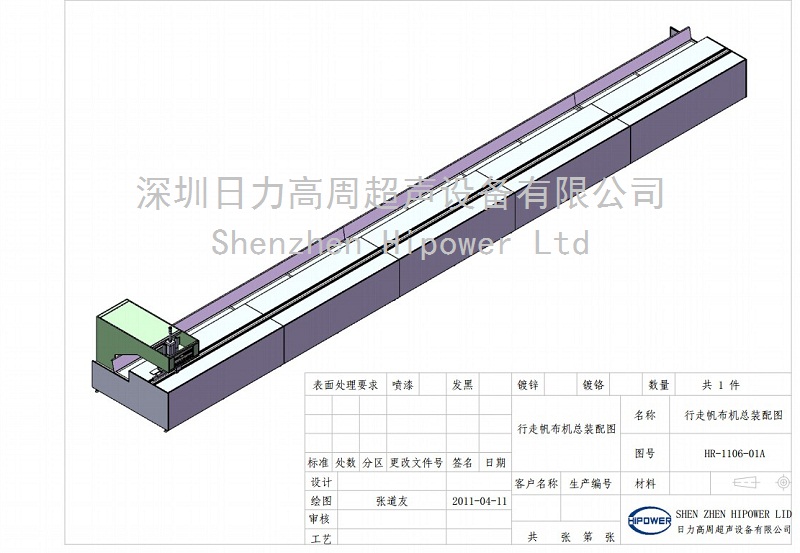

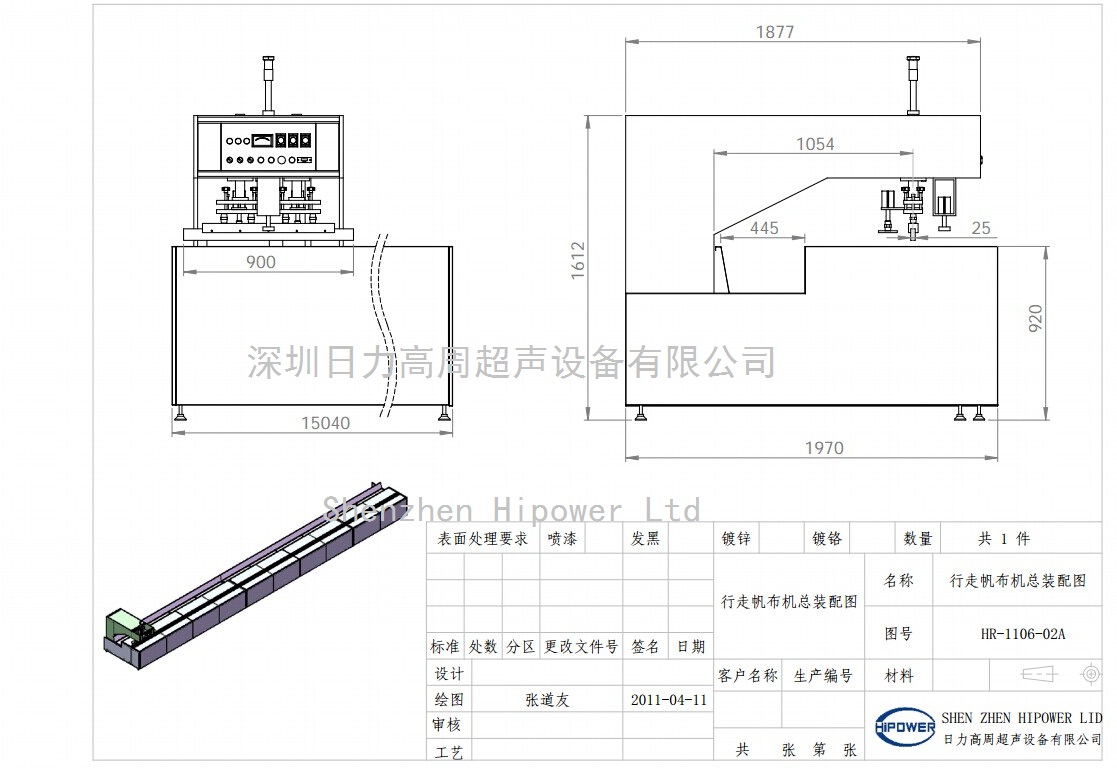

Machine Drawings:

Othere Models

Machine Drawings

Previous Products: High frequency industrial belt welding machine

Next Products: Printing cylinder welding and curling machine