- Product Display

- Product Display > High Frequency Welding Machine > Automatic Blister Packaging Machine

Turntable HF Blister & Card Sealing Machine

| Model: | HR-10KW-4AC |

| Scope Of Application: | Applied for blister packaging: LED packaging, blister and card sealing, blister and blister sealing... |

| Features: | CE certificate; welding and cutting machineAutomatic turntable. |

Multipurpose Turntable High Frequency Blister Sealing Machine

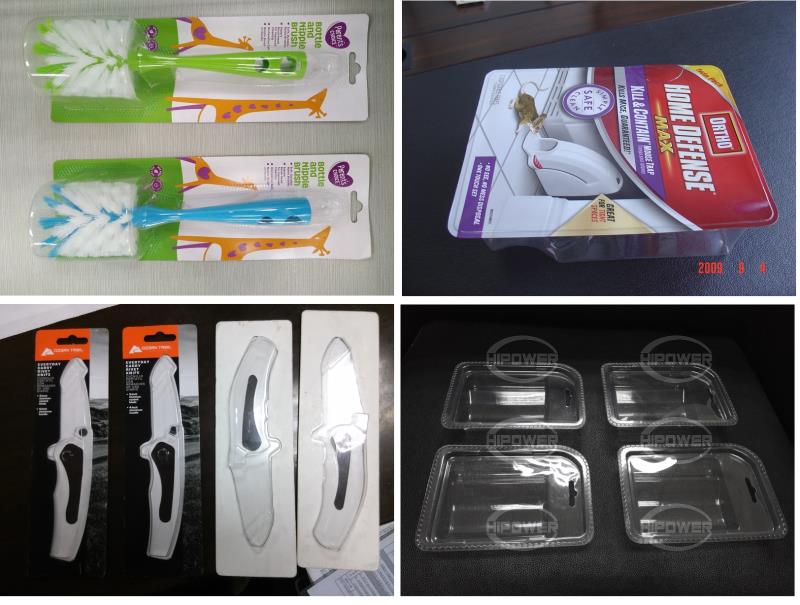

Application:

1. To seal blister of PVC, PET, PET-G, PET-GAG, A-PET...

2. Clear blister packaging

3. Plastic clam-shell packaging

4. Plastic Blister with plastic blister packages

5. Plastic blister with cardboard packages

6. Positive/negative blister forming and packaging

It is especially designed for HF welding is a perfect machine for production of blister packages,

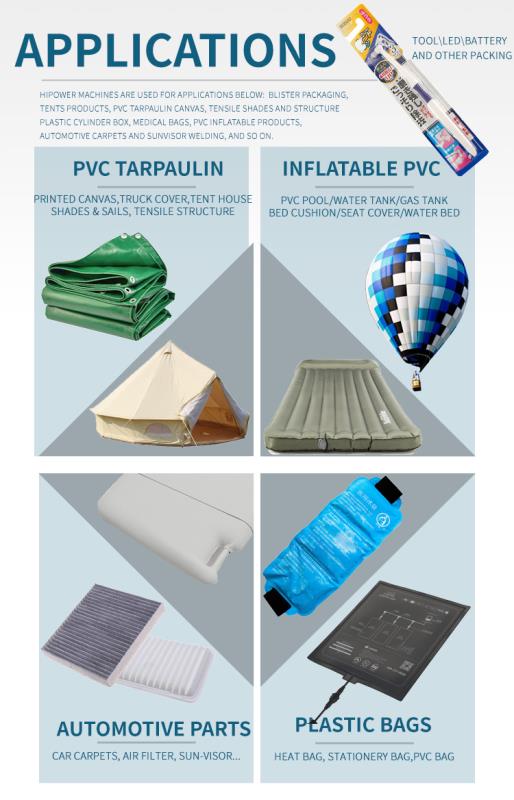

But it is multipurpose machine, for it can be used for industry like PU leather cover for pad,, safety vests, reflective signs, inflatable toys, cosmetics, folding packing box, automotive, medical, rehabilitation, packaging, recreation, textile and clothing, reflective garments,.etc.

The HF blister packaging welder series have HF power outputs from 5KW to 35KW 30kW for multi-cavity production loads and specialized products.

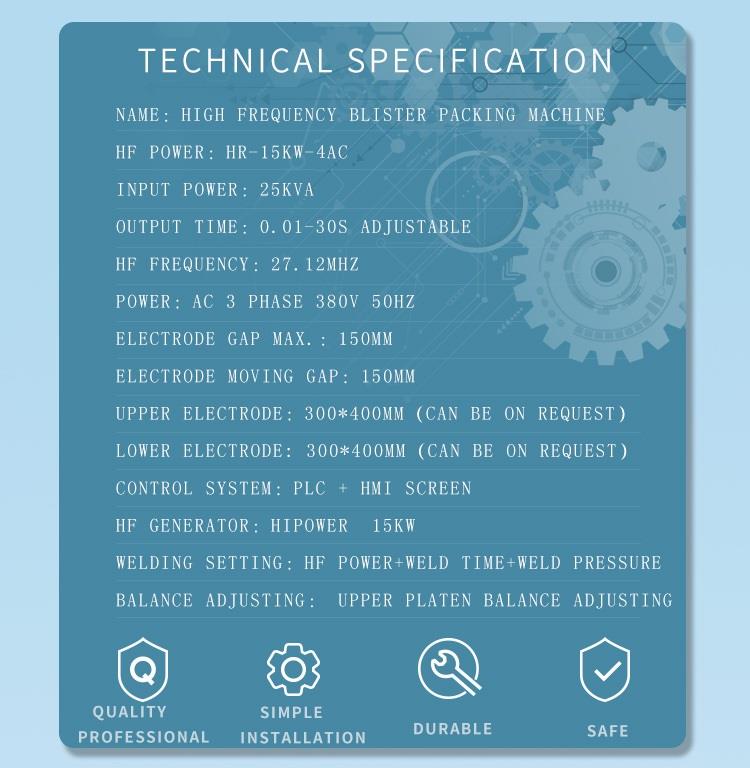

Specification:

Model HR-8000WET HR-10KWET HR-12KWET HR-15KWET

Output Power 8000W 10000W 12000W 15000W

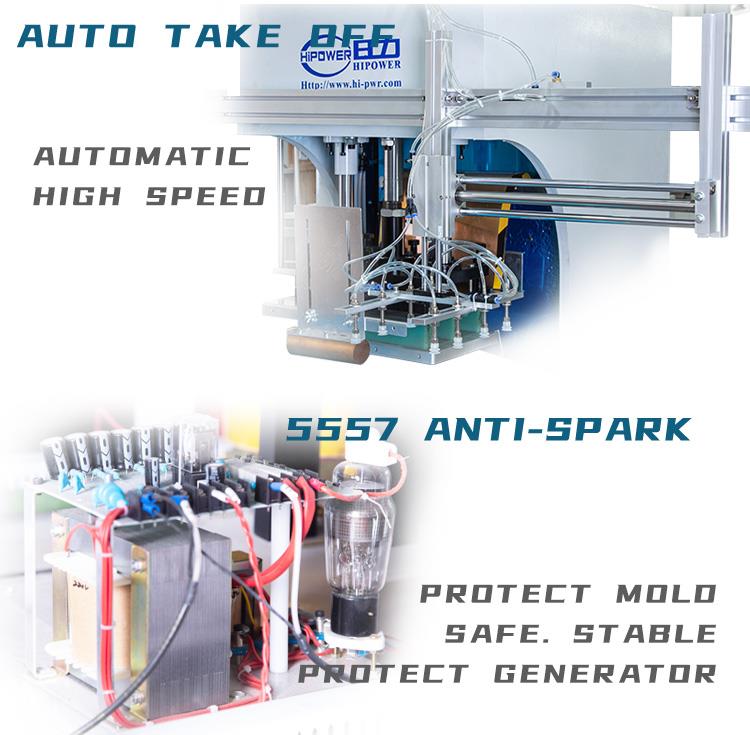

Anti-Spark System U.S.A. PL-5557 High sensitive anti-spark system

Voltage 3P AC 380V/220V/440V 50Hz-60HZ or customize

Frequency 27.12MHZ

Input power 15KVA 18KVA 20KVA 25KVA

Rectifier SILICON DIODE

Oscillation tube 7T69RB E3069 E3130 8T85RB

Max pressure 500kg 500kg 800kg 1000kg

Operation mode Pneumatic Operated (Hydraulic pressure upon request)

Max gap of electrodes 200mm

Size of active horn 150mm

Working Stations: Standard 3 ,4 , 6 , 8 Rotary work stations

Upper Electrode (W*H*L) 300*400mm 300*400mm 350*450mm 400*500mm

Size of Work Table (L*W) 350*450mm 350*450mm 400*500mm 400*500mm

Welding time 0.01~9.99s adjustable

Net weight 1500kgs 1500kgs 1500kgs 1500kgs

Foreseen productivity: 5/7 cycles/min depending on welding and rotating times, and operator skills

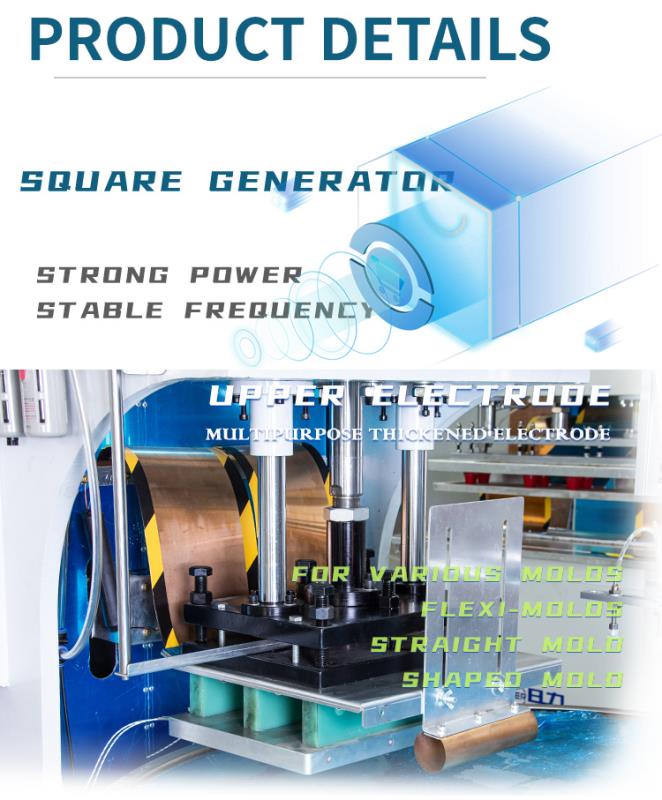

Machine General Features:

1. Anti-flash system, to protect the tooling / mould; C-Frame welded steel structure with integrated HF generator

2. Equipped with special high precision rotary indexing gear controlled by frequency inverter.

3. Automated HF weld cycles with adjustable rotating speed

4. With the use of touch screen HMI and programmable PLC operator can easily input parameters set.

5. Heated Upper platen with thermostat, for helping HF sealing process

6. Close off HF welding function, the machine can be use as Standard Heat Welder

7. Universal usage for PVC, PET-G,A-PET,GAG, PU, PET, PLA films

8. European-model square high frequency vibration box, more reliable and stable in output

9. CE rated machine; factory verified by SGS and BV;

10. Customer's site installation, training & maintenance available

11. Online service by Email, Fax, Video Online- allowing remote live video servicing of basic setup and repairs through the use of face-to-face online video.

12. High frequency welding press pneumatically operated

Optional Features:

1. Fully shielded HF weld area with side safety gate

2. Touch screen programmable HMI / PLC

3. Protective HF radiation shield standard

4. Auto-tuning system optional

5. Hydraulic pressure

Previous Products: High Frequency Blister Sealing and Cutting Machine

Next Products: High Frequency Welding Machine for breathing apparatus TPU breathing mask welding machine