- Product Display

- Product Display > PVC/PET Cylinder Tube / Foldable Box forming Machine > Plastic Box Crease & Die Cuttting Machine

High Frequency Soft Crease Box Forming and Die Cutting Machine

| Model: | HR-25KW-40T |

| Scope Of Application: | High Frequency Soft Crease Box Forming and Die Cutting Machine |

| Features: | Soft Crease Box FormingPVC/PET Die cutting |

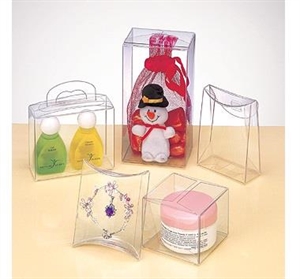

Application:

It is especially designed for Clear Packaging Boxes, soft crease box forming, PVC & PET folding box, Transparent Foldable plastic box making.

The plastic box can be made of PVC, PET, APET, PETG, GAG, and other Eco-friendly plastic films.

Depend on plastic material type: Film Sheets or Plastic Roll, you can choose a semi-auto machine, or an automated machine.

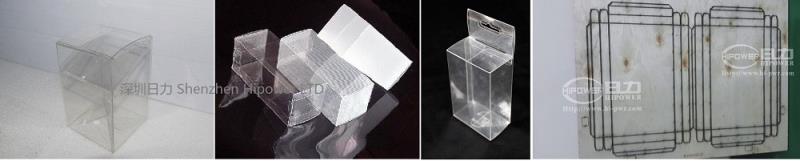

Products:

1. PVC Box 2. PET Box 3. PET-G Box

4. A-PET Box 5. GAG box 6. Other 30%PVC based Plastic packing box

Your customer will be happy to buy the products packed in clear / transparent plastic box, since they can know the products

clearly without opening the package.

On the other hand, the see-through packaging method attract attention of customers, young or old.

Model HR-15KW-30T HR-25KWP-40T

Output Power 15000W 25000W

Anti-Spark System U.S.A. PL-5557 High sensitive anti-spark system

Voltage 3P AC 380V/220V/440V 50Hz-60HZ or customize

Frequency 27.12MHz +/- 0,6 % / 13.56MHZ +/- 0,6 %

Input power 25KVA 25KVA

Rectifier SILICON DIODE

Oscillation tube 8T85RB 8T25RA

Max pressure 800kg 800kg

Operation mode Pneumatic Operated

Max gap of electrodes 150mm

Size of active horn 150mm

Upper Electrode (W*H*L) 700*800mm 800*900mm

Size of Work Table (L*W) 700*800mm 800*900mm

Welding time 0.01~9.99s adjustable

Mould Heating Temperature 30-200℃ Adjustable

Net weight 1500kgs 1500kgs

Foreseen productivity: According to welding times and operator skills

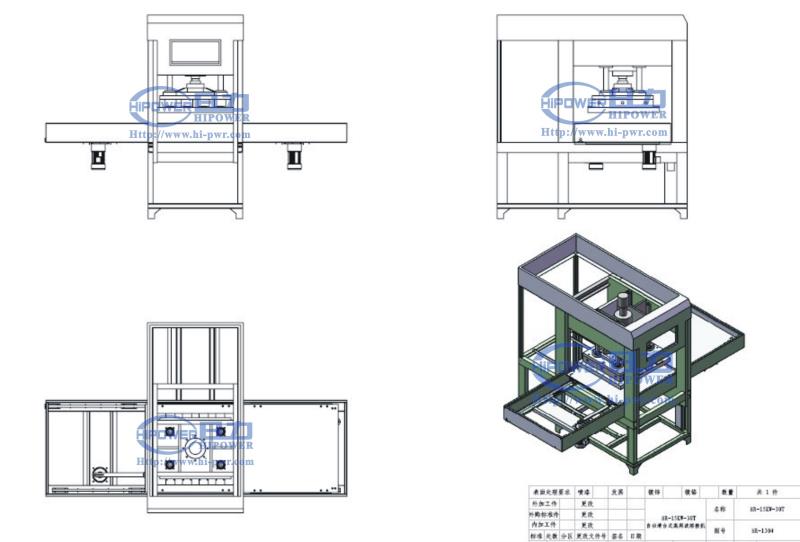

Machine Views:

Machine General Features:

1. Length, width and radian of welding area can be adjusted by change welding die.

2. European-model square high frequency vibration box, more reliable and stable in output

3. Automated Three-in-one machine :

auto film flattening----(Optional: auto offset printing)---auto soft crease forming & waste scrap cutting

4. PLC & HMI Touch screen operated, making the operating process simple and time-saving

5. Servo-motor automated, enables exact off-set printing effect, box & scrap cutting performance

6. Separated Continuous Oil heating flatten system, PET, PETG, GAG.. Plastic flatten is available

7. High frequency welding press Sole hydraulic operated (two phase pressing: The first phase for soft crease forming,

The second phase for waste scrap cutting)

8. High sensitive 5557 anti-flash system to protect the welding Mould

9. Human oriented mechanical frame design

10. Mould heating function available, enables beautiful soft crease forming.

11.Customized work table dimensions, electrode holder dimensions, tooling

12. Online service by Email, Fax, Video Online- allowing remote live video servicing of

basic setup and repairs through the use of face-to-face online video.

13. Customer's site installation, training & maintenance available

14. CE rated machine; factory verified by SGS and BV;

Optional Features on Request:

1.Off-set printing Unit available

2. HF Filter unit available

3. Auto-high frequency tuning technology

4. High frequency generator on separate cabinet

Previous Products: Moving Canvas/Tarpaulin Welder by High Frequency Welding

Next Products: Radio Frequency Cylinder Bottom Sealing Machine