- Product Display

- Product Display > Ultrasonic Welding Machine > Standard Ultrasonic Welding Machine

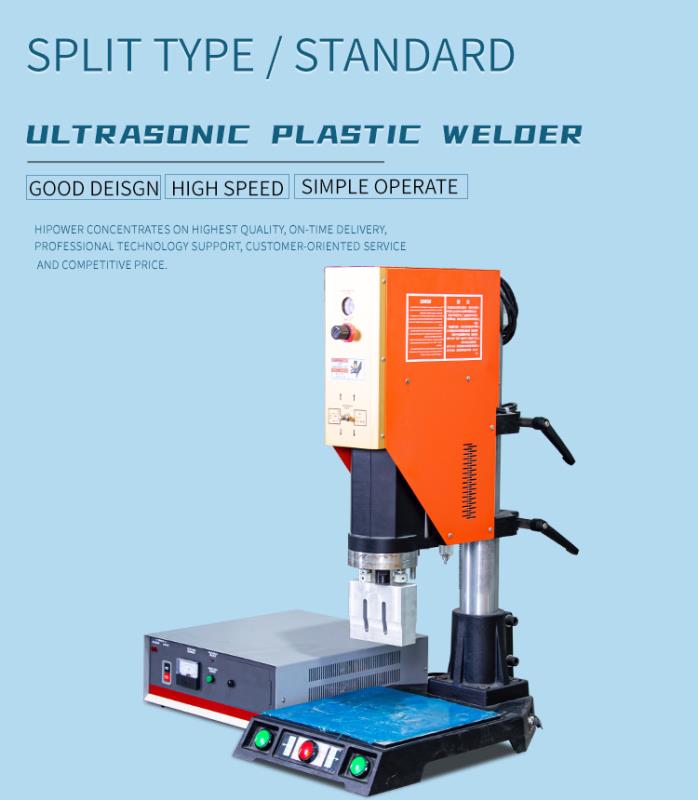

HC-2615 New design Ultrasonic Plastic Welding Machine

| Model: | HC-2615 |

| Scope Of Application: | Applied for ultrasonic welding of ABS,PE,PC,PS,PVC,PP,ABS and PC Complex, Acrylic and Relatives |

| Features: | The straight line guide bearing, the precise matching deviceThe horizontal zoom type structures of four corners allocate that the board four corners at bottom can transfer the standardJapan Huang Paigang becomes a ware, and the horizontal zoom type st |

New design Ultrasonic Plastic Welding Machine Series

Name: HC-2615 2600W 15KHz Ultrasonic Plastic Welding Machine

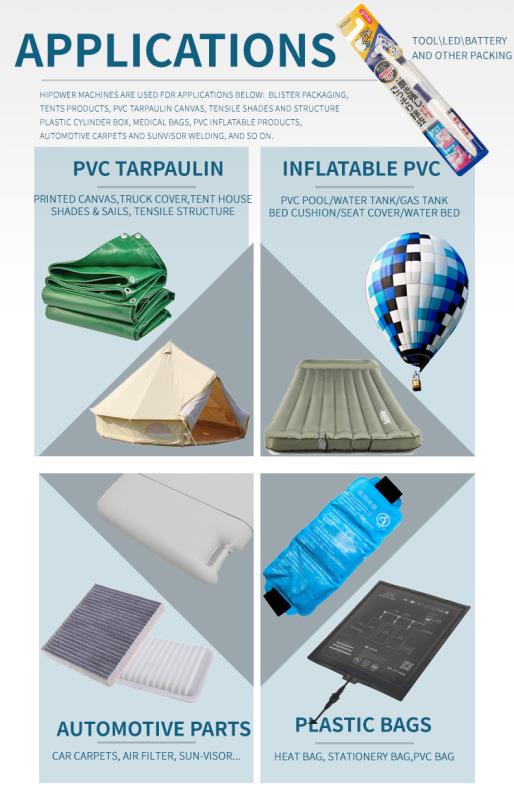

Applied range of Ultrasonic welding machine:

Widely used in aviation, boats, cars, electrical appliance, package, toys, electric, medical, auto parts, fishing and textiles etc.

For example: disposable transfusion filter, blood plasma whizzer, valve bag, plastic wine bottle cap, dish washer waterwheel, plastic toys, car lamp,plastic fake bait, charger shell and mobile hanging drop welding, disposable lighter shell welding etc. Besides: car door plaque welding, car motormeter welding, car lamp car mirror welding, sun visor welding, car inside accessories welding.Apply for ABS, PE, PC, PS, PVC, PP, ABS & PC complex, Acrylic etc. materials.Character:

The straight line guide bearing, the precise matching device.The horizontal zoom type structures of four corners allocate that the board four corners at bottom can transfer the standard. Japan Huang Paigang becomes a ware, and the horizontal zoom type structure of lasting durable horn allocates that the board four corners at bottom can dive flatly

Product Introduction:

1.Ultrasonic welding: Ultrasonic Vibration transmit the energy via welding horn to plastic workpiece surface, generating localized hyperthermia to melt the plastic surface. Under pressure of the ultrasonic welding machine, make 2 pieces of plastic workpiece to weld, get a good-looking and stable entire product.

2.Ultrasonic embedding: Putting screw, nut or other metal into plastic workpiece.via transmitting ultrasonic energy to the metal. After highly speed vibration produce heat, make the metal directly embed into the plastic workpiece under ultrasonic machine pressure.3.Ultrasonic riveting: To make metal and plastic or 2 pieces of different materials plastic weld together, you can use ultrasonic riveting, to make the welding product not easily brittlemen, elegant looking and stable.

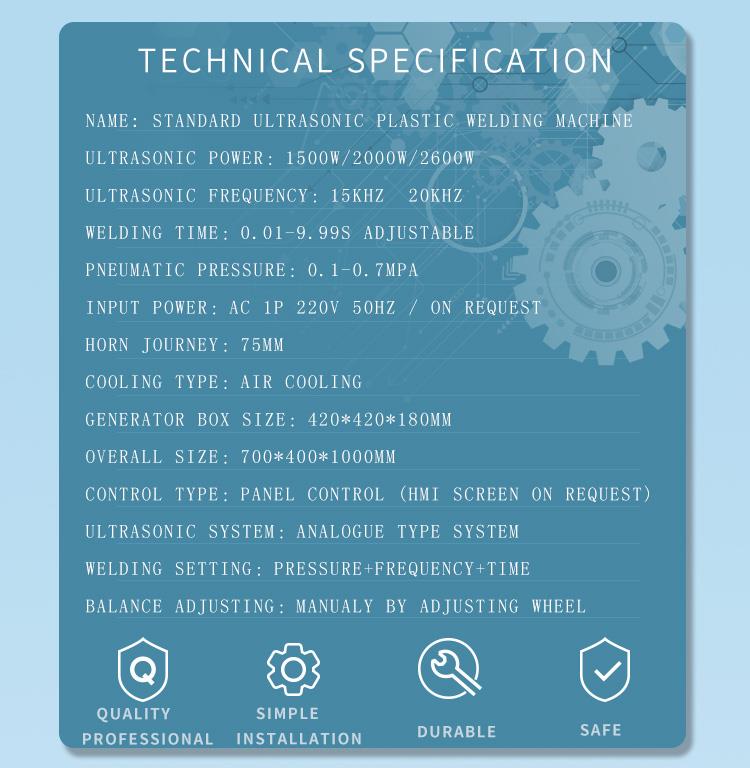

ultrasonic machine technique parameters:

|

Model |

HC-2615 HC-3215 HC-4215 |

|

Input power |

2600w 3200W 4200W |

|

Frenquency |

15KHZ |

|

Input voltage |

220V |

| The Max Input Power | 1.2KW 1.9KW 2.3KW |

|

The moving distance of active horn |

70mm |

|

Oscillation system |

Auto-stimuilating |

|

Output time |

0.01-99S |

|

Pressure |

Pressure bound 2-7bar |

|

Welding area |

∮200mm ∮220mm ∮250mm |

|

Compressor |

1HP-2HP |

|

NET |

110kg 110kg 115kg |

Sample view:

Previous Products: HC-2020 Standard Ultrasonic Plastic Welding Machine

Next Products: HC-1520 Ultrasonic plastic welding machine for PVC